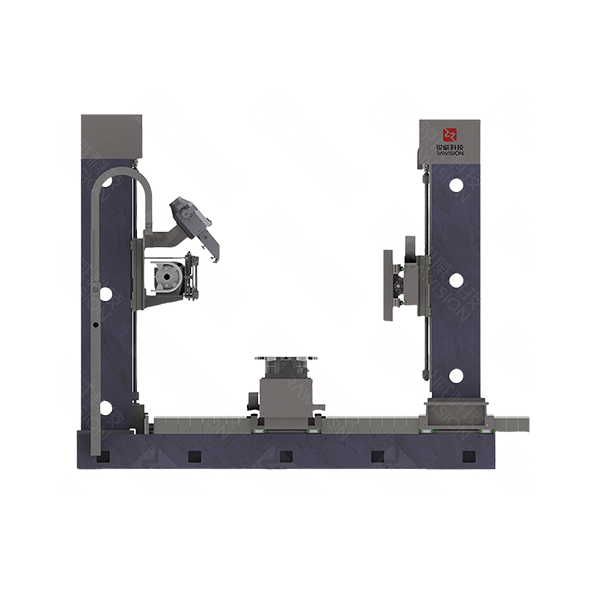

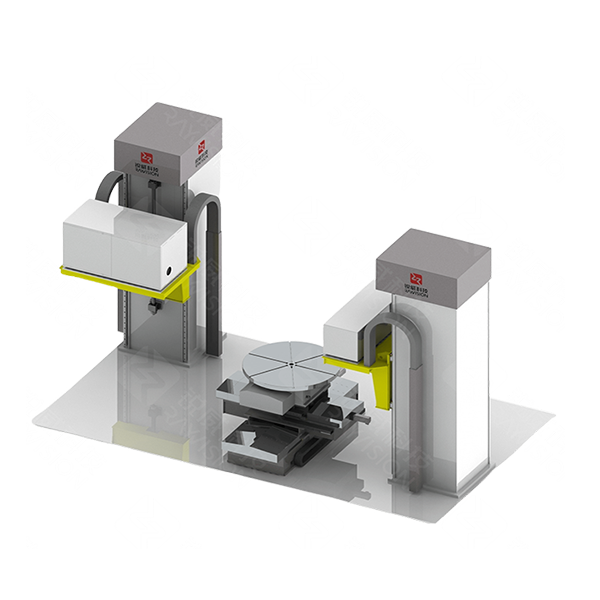

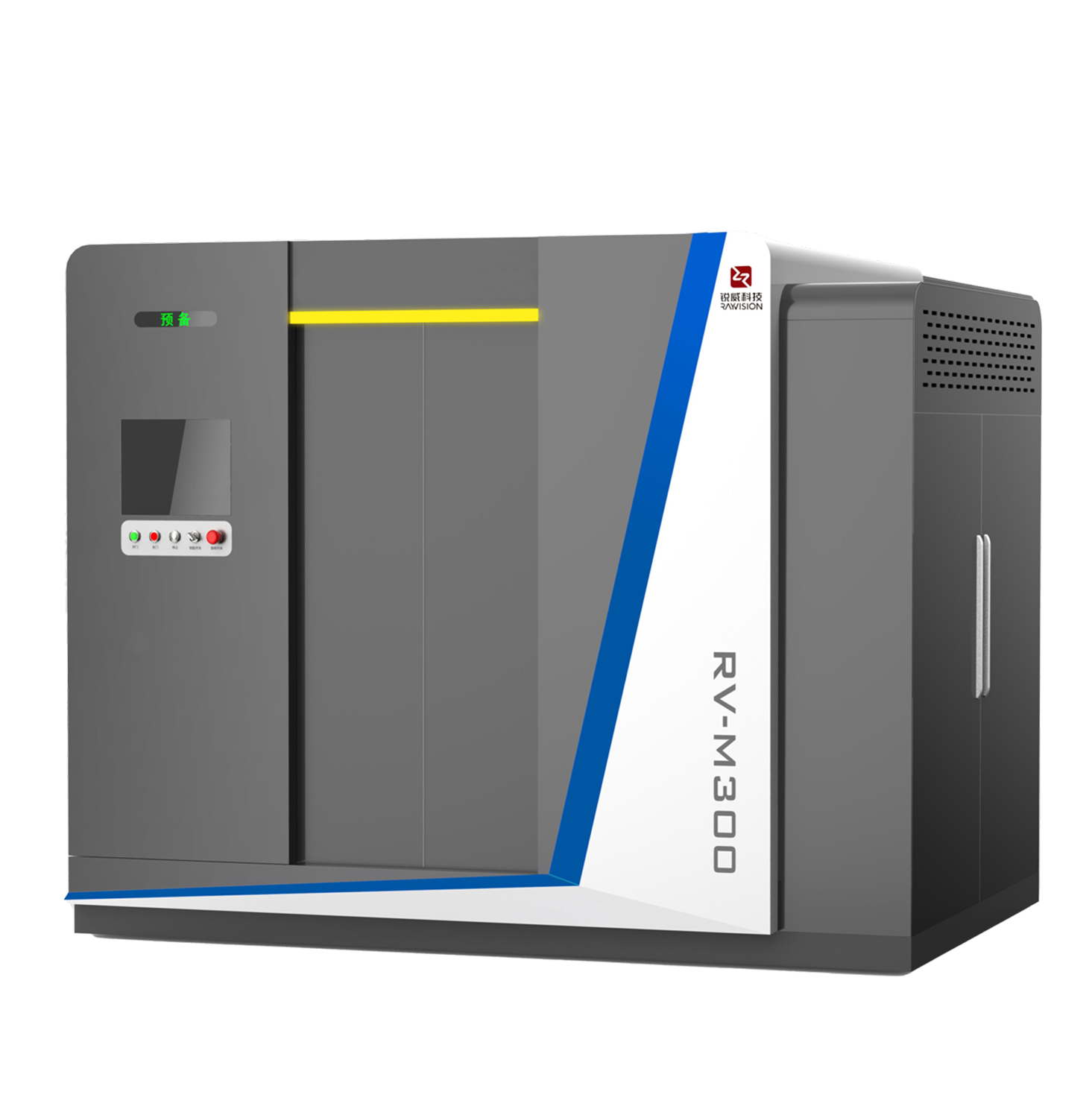

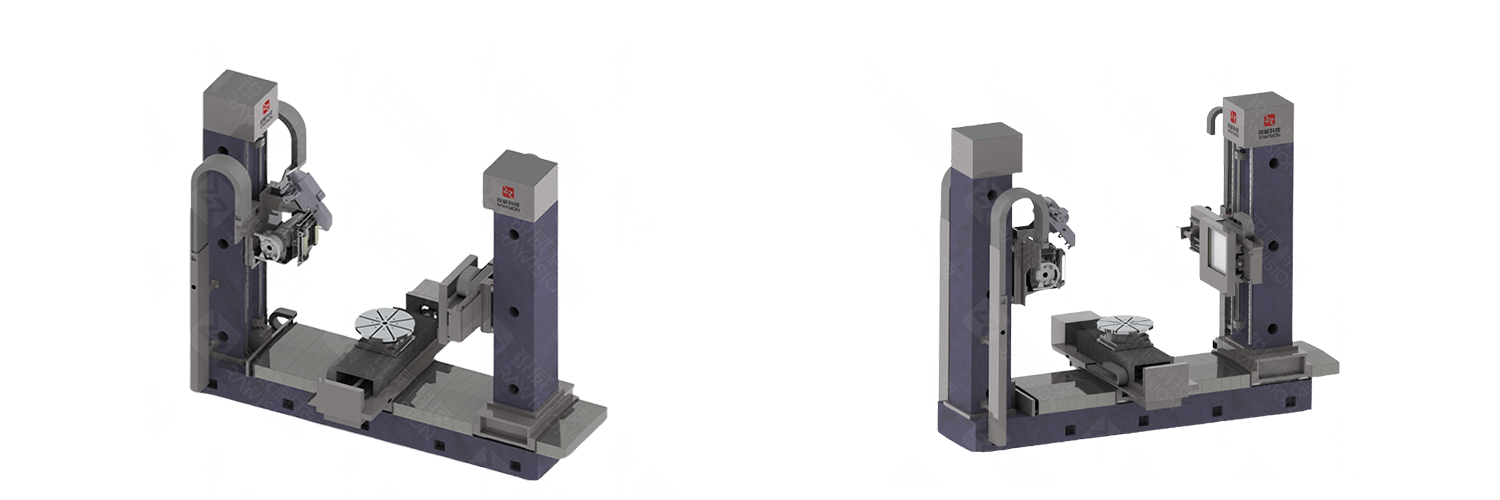

RV-G series

The RV-G series industrial CT inspection system uses 160~600kV X-ray machine as the ray source, and can be equipped with 225/300kV micro-nano focus ray source. The system is equipped with line detector and area detector, image analysis, processing and recognition software, which is powerful, fast imaging speed and clear image. It is mostly used to detect different sizes of aviation and aerospace parts, auto parts, composite materials, metal/ceramic parts, etc., and can be used for internal defect (such as cracks, porosity, inclusions, porosity, etc.) analysis, porosity measurement, wall thickness analysis and structural dimensional accuracy measurement of workpieces.