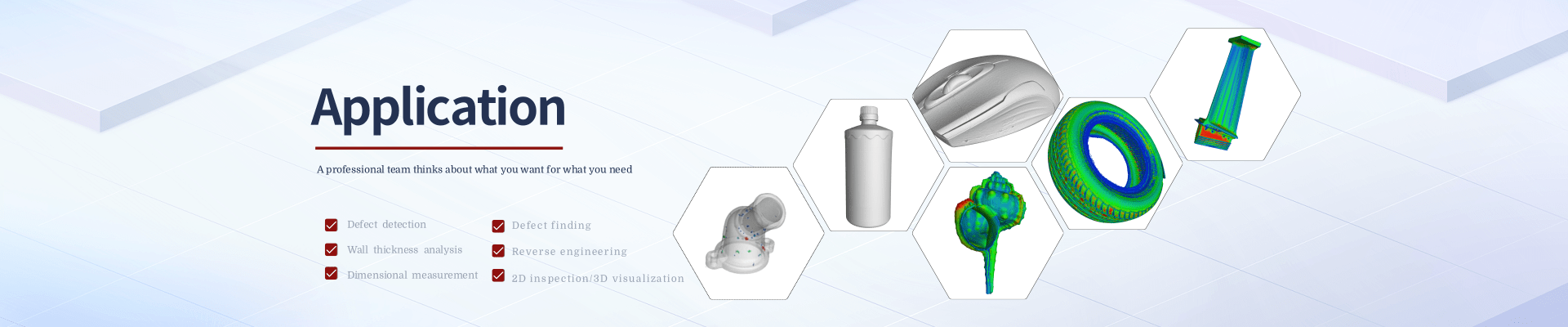

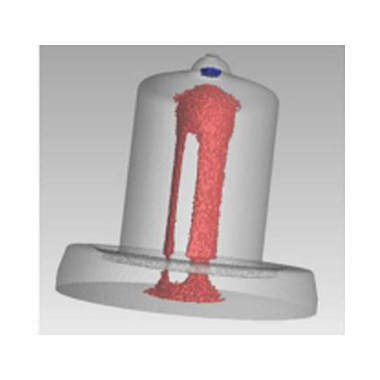

Cars

The industrial CT detection system is widely used in the automotive industry for quality assurance in the development process and non-destructive testing in the maintenance process. By using computer tomography to capture three-dimensional images of tires, tires, wheel units, and electromechanical components, the obtained images are used for three-dimensional geometric measurement of tire structural components, plastic models, or packaging components. It is suitable for non-destructive tire detection, defect detection of semiconductor components, electronic devices, tires, and composite rubber and rubber composite material components without disassembly.

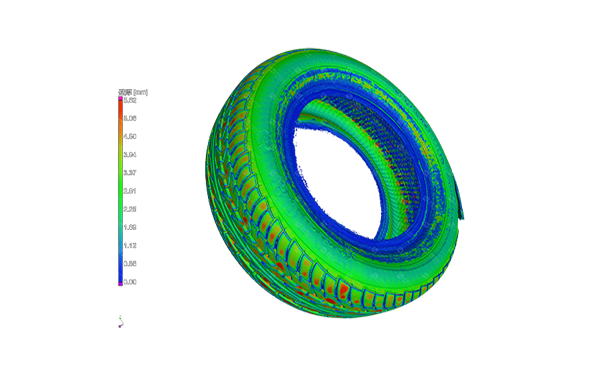

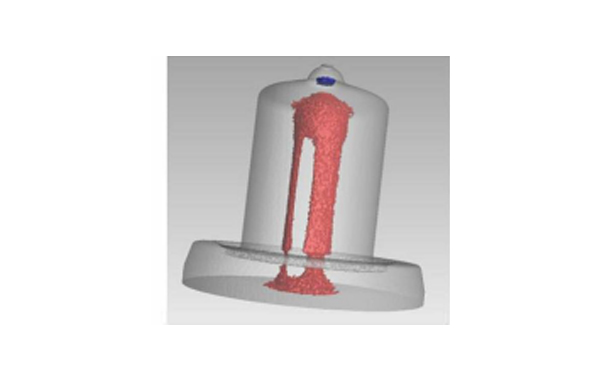

▎Defect detection

Suitable for detecting internal defects in metal and non-metal products and materials.

Automatically detect and analyze defects such as pores, cracks, inclusions, and shrinkage cavities.

Detected defects are color coded and visualized in 3D based on their size

Three-dimensional visualization and localization of defect distribution.

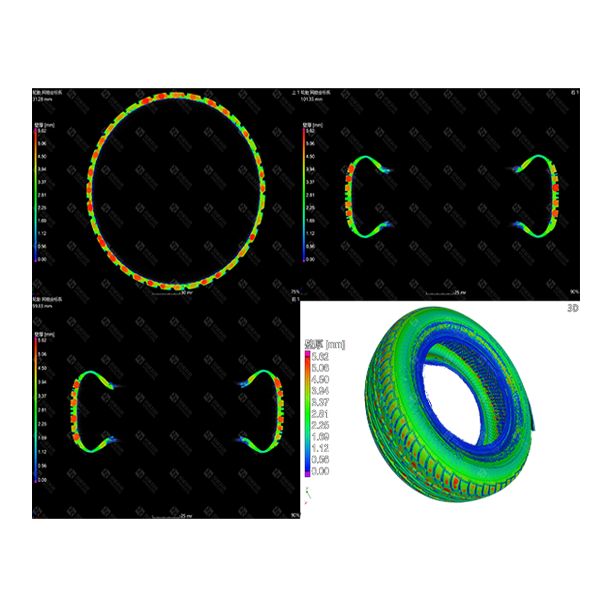

▎Thickness analysis and dimensional measurement

Conducting overall or local thickness analysis on the parts to obtain the thickness at each position.

Displaying different thicknesses with color coding and gradient identification.

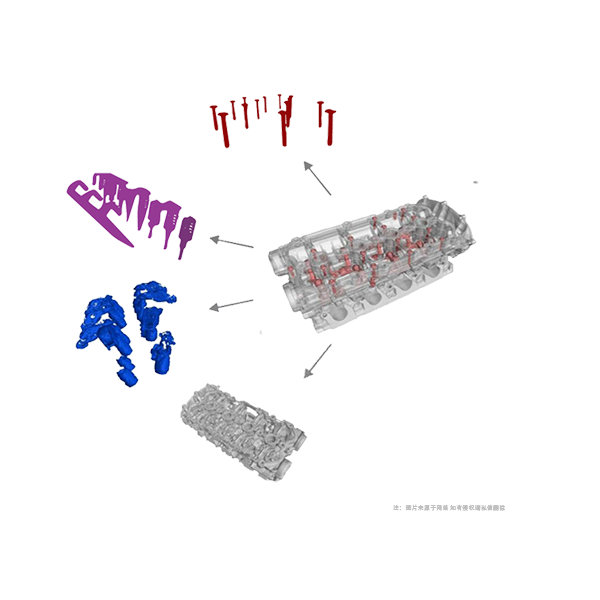

▎Reverse Engineering

CT scanning of complex assembled products;Easily obtain 3D images of each individual part;Obtain the internal structure of complex products

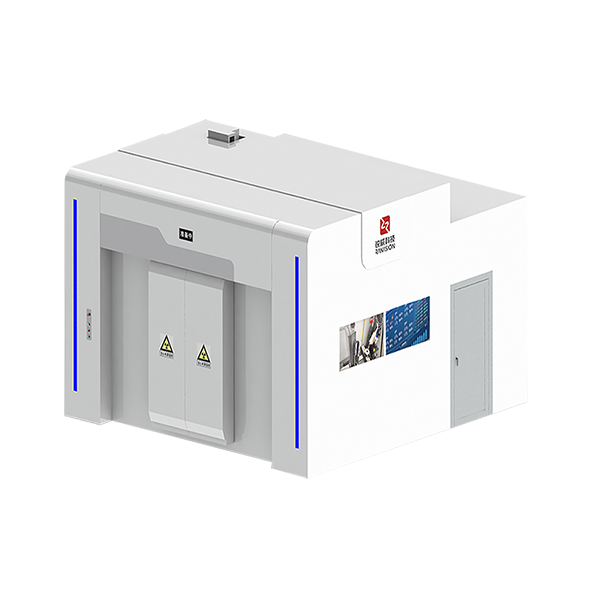

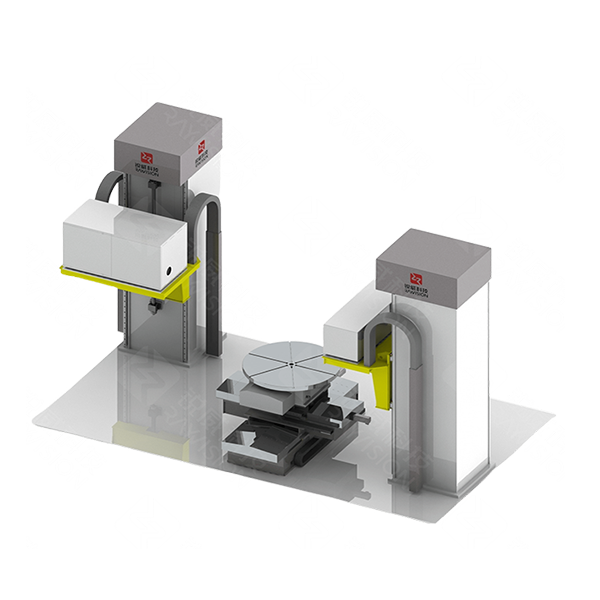

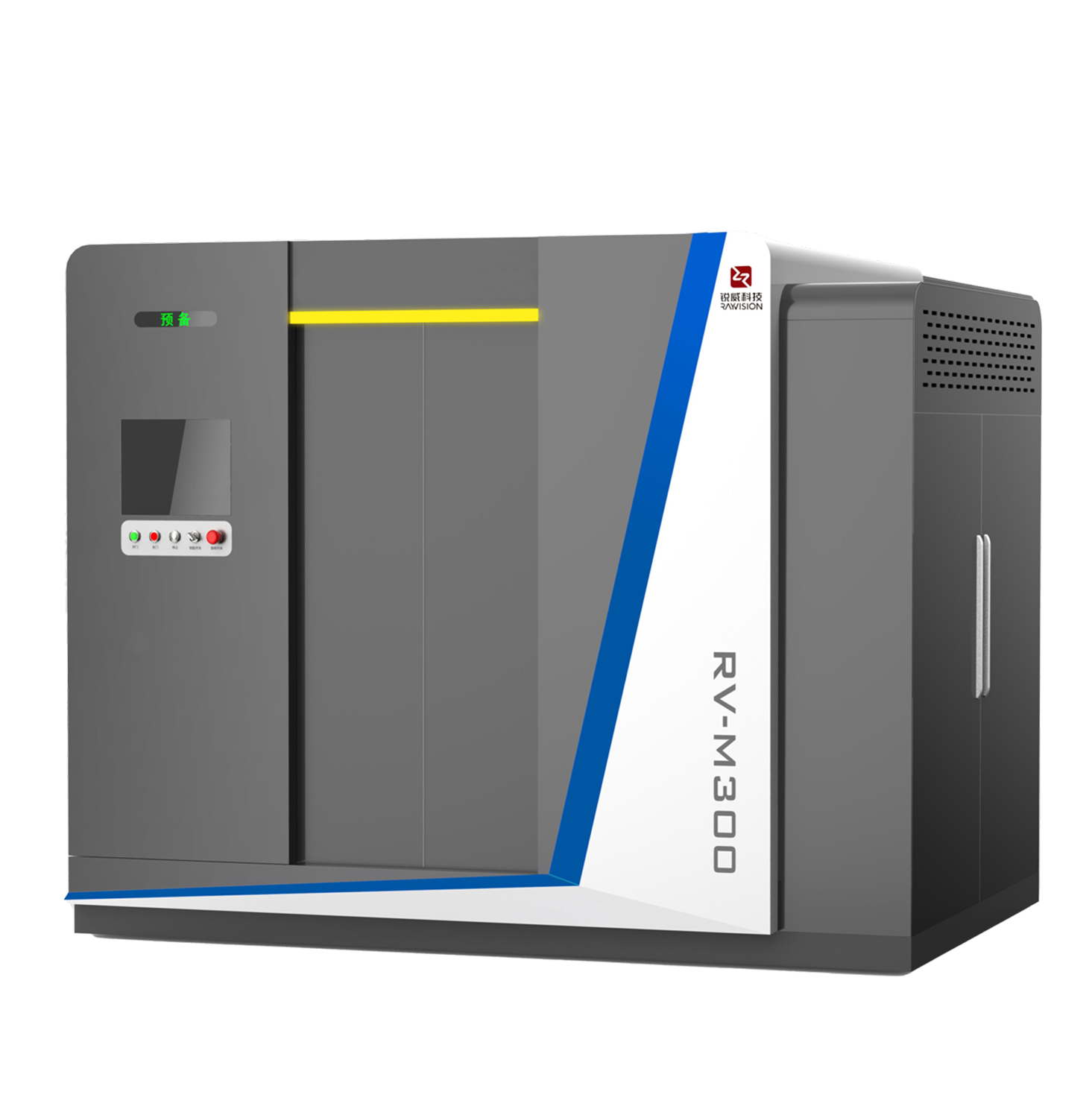

▎Product Recommendations