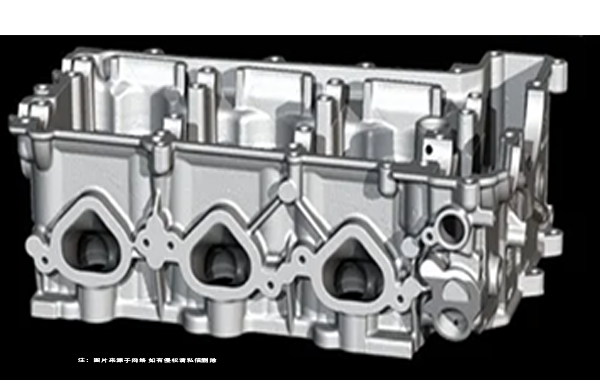

Casting Parts

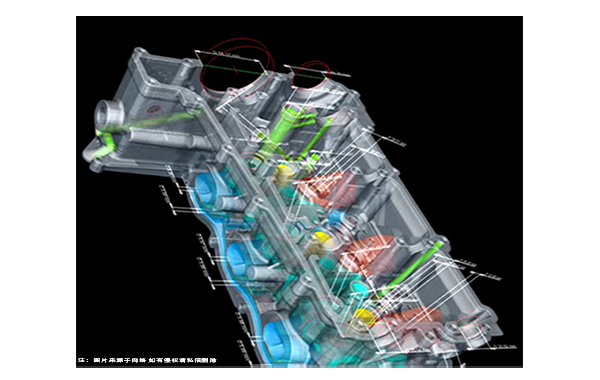

Industrial CT testing can be used to detect defects (such as porosity, bubbles), analyze hot cracks, dimension changes, and inclusions in typical cast products such as iron, magnesium, aluminum, zinc, or stainless-steel materials.

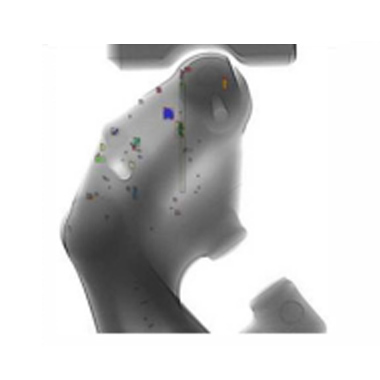

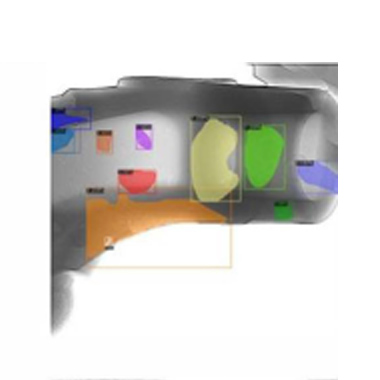

▎Automatic Defect Recognition

Can achieve defect classification and feature extraction;Extract a three-dimensional distribution map of defects;Quickly and accurately identify defects, with high efficiency and accuracy;2D and 3D inspection of castings, with clear observation of internal defects

Automatic recognition of defects in automotive castings

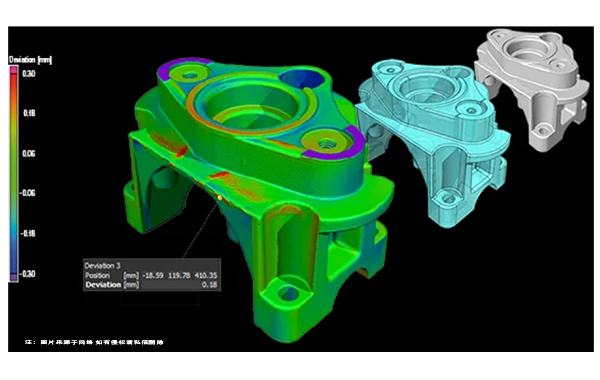

▎Dimensional Measurement

Accurately measure the dimensions of the internal and external structures of the parts;Can perform two-dimensional or three-dimensional measurements of internal and external structural dimensions;Dimensional measurement accuracy can reach the micrometer level

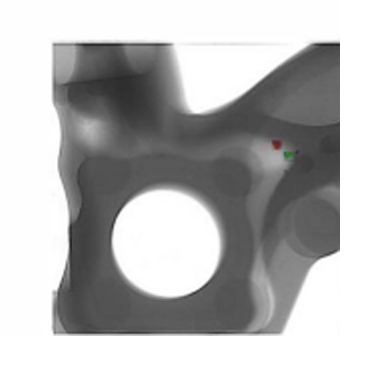

▎Analysis of Pores and Inclusions in Large Castings

Quickly and objectively detect casting defects, such as voids, inclusions, etc;Large castings are spliced and scanned;Analysis of internal pores and inclusions in castings;Histogram of pore diameter distribution and pore volume distribution

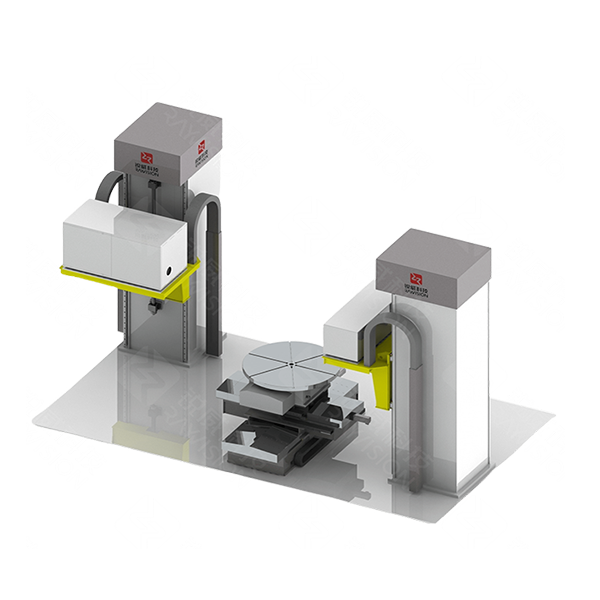

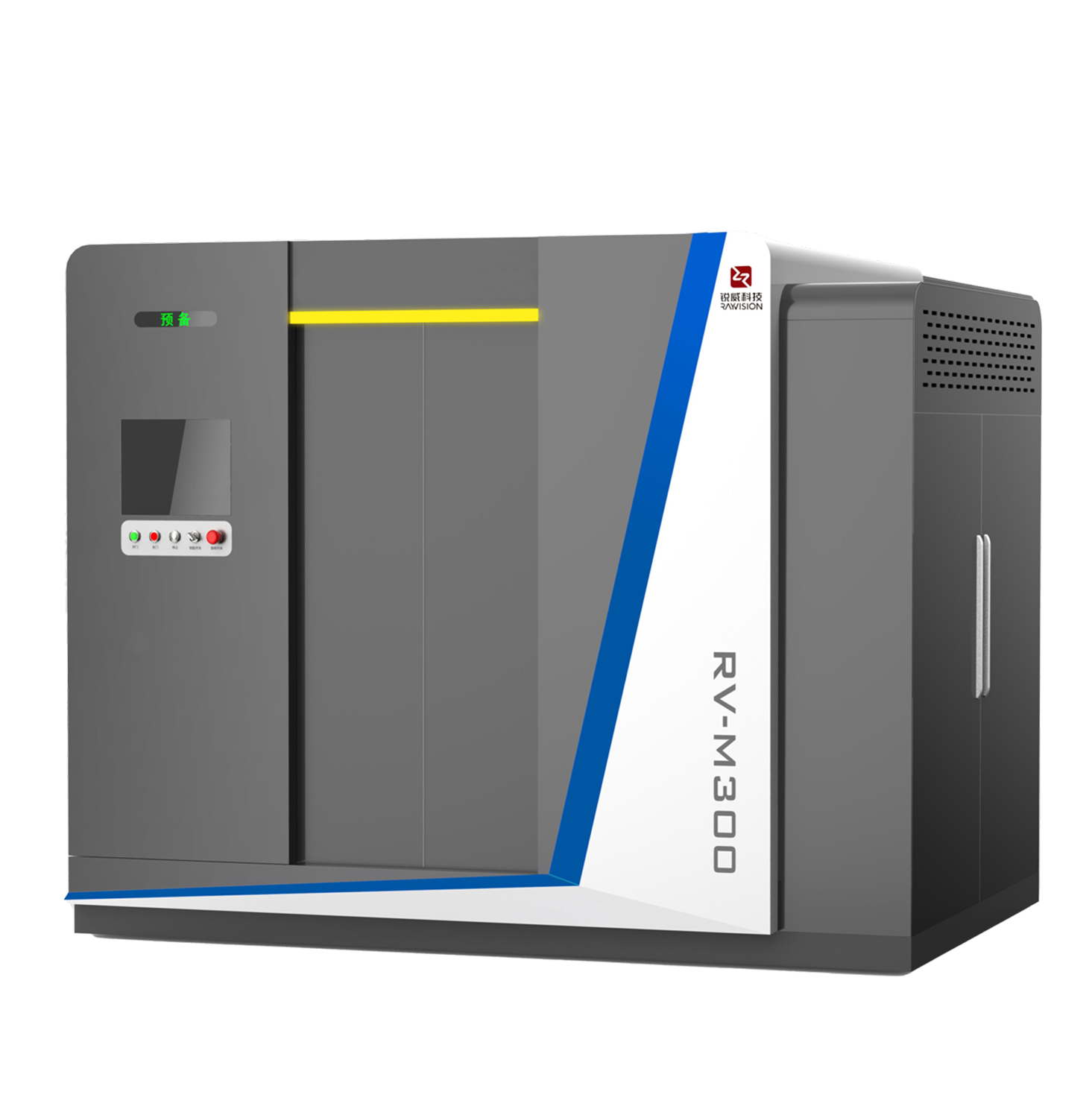

▎Product Recommendations